close

Choose Your Site

Global

Social Media

FOACHI Hardware provides a comprehensive range of door handles crafted for performance, durability, and modern aesthetics. Designed for residential, commercial, and architectural projects, our handles combine ergonomic comfort with engineered precision, available in aluminium, zinc alloy, and stainless steel to meet every environmental and functional requirement.

Each handle is manufactured using high-grade materials, precision machining, and advanced surface treatments such as anodizing, electroplating, and PVD coating. Whether for interior home use, high-traffic hotel doors, or industrial facilities, FOACHI delivers door hardware that performs reliably while complementing every design style.

Aluminium Door Handles

Zinc Alloy Door Handles

Stainless Steel Door Handles

Lightweight and corrosion-resistant, ideal for modern interior doors, wardrobes, and minimalist designs.

Available in matte black, brushed silver, champagne, and custom colors.

Engineered for strength and visual elegance. Perfect for hospitality and commercial use, featuring refined plating finishes and a premium tactile feel.

Built for longevity and strength. Suitable for coastal areas, exterior doors, and public buildings where corrosion and durability standards are critical.

| Parameter | Description | Example |

|---|---|---|

| Model No. | Unique product code | A038-E03 / Z1-1 / SS-01 |

| Material | Base composition | Aluminium Alloy / Zinc Alloy / Stainless Steel 304 |

| Finish Options | Surface treatment | Brushed / Polished / Matte Black / PVD Gold / Satin Nickel |

| Handle Length | Grip bar size | 120 mm – 145 mm |

| Rosette/Base Size | Mounting plate | 53 × 53 mm (square) / Ø53 mm (round) |

| Door Thickness Range | Installation range | 35–50 mm |

| Spindle Size | Lockset shaft dimension | 8 × 8 mm |

| Backset Compatibility | Lock case fitting | 50 mm / 60 mm |

| Opening Direction | Left / Right reversible | Universal fit |

| Mechanical Test Cycles | Durability rating | ≥ 200,000 cycles |

| Corrosion Resistance | Neutral salt spray test | 72 – 120 hours |

| Fire-Rated Option | On request | 60 – 90 mins certified |

| Application | Recommended environment | Residential / Commercial / Industrial |

| Packaging | Export standard | 1 set / poly bag / box, 20 sets / carton |

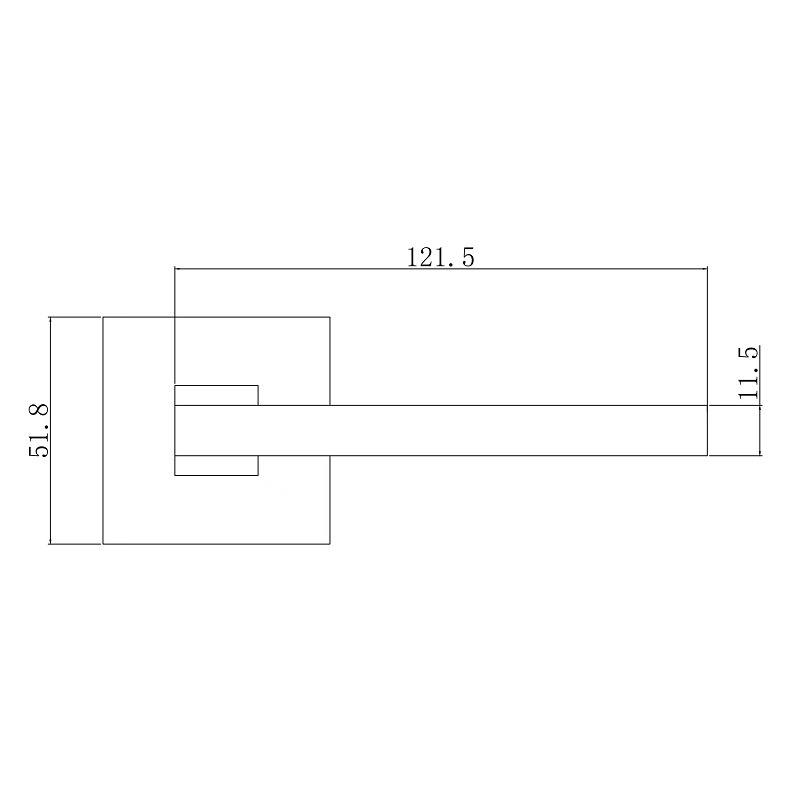

This handle features a sleek, minimalist design with precise dimensions of 121.5 mm in length, 51.8 mm in base height, and a handle thickness of 11.5 mm.

Such compact sizing is ideal for modern interior doors, ensuring a balanced visual profile and comfortable grip.

The square backplate design allows seamless installation on aluminum and wooden doors, maintaining a contemporary aesthetic.

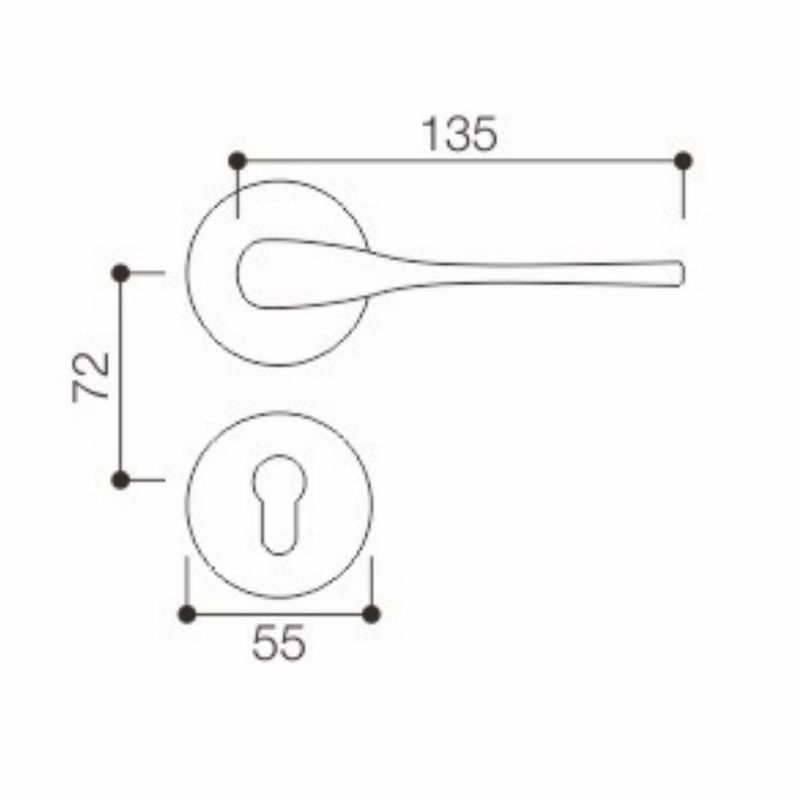

The zinc alloy handle adopts a circular rose configuration, offering both style and functionality.

With a total length of 135 mm and a rose diameter of 55 mm, this model emphasizes ergonomic curvature for comfortable operation.

Its 72 mm spacing between handle and keyhole enhances usability, making it a preferred choice for residential and commercial doors where visual harmony matters.

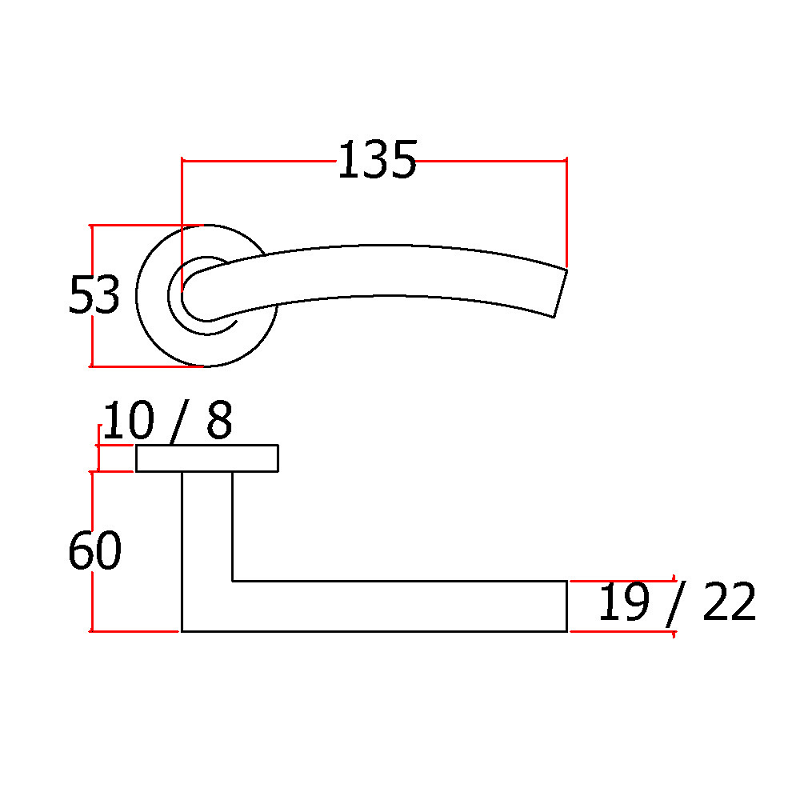

This stainless steel model highlights a robust and durable structure suitable for high-traffic or industrial environments.

Key parameters include 135 mm handle length, 60 mm projection, and a 19–22 mm lever diameter, ensuring firm grip and extended service life.

The curved ergonomic profile provides smoother operation and complies with most universal door standards, blending strength with comfort.

Tested for 200,000 opening cycles under EN 1906 Grade 3–4.

Precision-machined internal mechanism for smooth rotation (≤ 2.5 N torque).

Enhanced corrosion resistance through advanced plating or anodizing.

Produced in ISO-certified facilities with 100% quality inspection.

FOACHI supports OEM / ODM manufacturing to fit diverse architectural needs.

Choose handle geometry — round, square, lever, or flat.

Custom color and coating: powder-coated, anodized, chrome, nickel, PVD.

Logo engraving, size modification, and packaging customization available.

CAD & BIM files offered for professional project integration.

Measure and mark drilling holes based on included mounting template.

Insert spindle through lock body.

Secure handles using M6 screws and test alignment.

Snap on rosette cover to hide screws and achieve a clean look.

Suitable for: Standard 35–50 mm doors, latch or mortise lock systems.

Clean regularly with soft cloth and neutral detergent.

Avoid abrasive or acidic cleaners to protect surface finish.

Apply lubricant to moving joints every 6 – 12 months.

Average service life: 10 + years in typical indoor conditions.

| Feature | Aluminium Handle | Zinc Alloy Handle | Stainless Steel Handle |

|---|---|---|---|

| Durability | ★★★★☆ | ★★★★☆ | ★★★★★ |

| Corrosion Resistance | ★★★★☆ | ★★★ | ★★★★★ |

| Weight | Light | Medium | Heavy |

| Best Use | Interior / Light-duty doors | Hotels / Furniture / Offices | Exterior / Industrial / Public spaces |

| Customization | High | Very high | Medium |

| Price Range | $ | $$ | $$$ |

Each handle set individually wrapped in protective foam and color box.

Export carton packing with model labeling and barcode tracking.

OEM / ODM packaging support for distributors and project branding.

Lead time: 15 – 25 working days, depending on order quantity.

Residential: Bedroom, bathroom, living room, sliding and wardrobe doors.

Commercial: Offices, hotels, showrooms, schools, retail spaces.

Industrial: Warehouses, plant rooms, public facilities, coastal environments.

Architectural projects: Modern interiors and high-traffic environments requiring durable hardware.

Door handles vary widely: lever on rose, lever on back-plate, pull handles, surface mounts, etc. When choosing, consider door material, usage scenario (interior vs exterior), disability or accessibility requirements, and design style.

Handles made from stainless steel or suitably coated aluminium perform best in salty or humid environments due to superior corrosion resistance. This is a common concern especially for exterior or public-space hardware.

Not always. While some dimensions like spindle size (often 8 mm) and backset may be standard, handle lengths, rosette sizes and mounting hole patterns vary. Always check your door’s thickness, lock case dimensions, and mounting template before choosing.

Installation usually involves: removing the old handle, aligning the spindle with the lock or latch case, mounting the new handle or rose, tightening the fixing screws, and testing for smooth operation. Many guides highlight this process for users.

Use a soft cloth and mild soap solution to clean; avoid harsh acids or abrasive cleaners. For plated or coated finishes, regular gentle cleaning preserves appearance and prevents corrosion. Lubricate moving parts as recommended.

While local codes vary, typical ergonomic and accessibility standards suggest installing handles around 34–48 inches (≈860–1220 mm) from the floor for ease of use.

Yes. Many manufacturers—especially those serving architectural and commercial projects—offer OEM/ODM services for custom sizes, finishes, colors, and branding. This flexibility is highly valued by designers and project specifiers.

High-quality handles are typically tested to tens or hundreds of thousands of cycles. Proper installation and maintenance can yield service lives of 10 years or more in residential settings, and even longer in commercial settings when well maintained.

Samples are available within 3–5 working days; OEM and ODM customization are supported for bulk orders.

Brushed nickel, chrome, matte black, satin gold, and custom powder coatings.