close

Choose Your Site

Global

Social Media

Foachi Hardware presents a full range of zinc alloy door handles designed for strength, style, and lasting performance. Our handles are crafted with precision to deliver smooth operation, corrosion resistance, and modern aesthetics that suit both residential and commercial spaces.

Whether you need sleek matte black handles for contemporary interiors or elegant satin nickel finishes for luxury projects, Foachi’s zinc alloy range offers versatile solutions for every door system.

Zinc alloy door handles are known for their durability and robustness, capable of withstanding frequent use in high-traffic areas. The material provides structural strength without the excessive weight of solid brass or steel.

Available in matte black, polished brass, satin nickel, antique copper, and chrome, zinc handles match various décor styles—from minimalist modern to vintage classic. The electroplated finish also adds superior corrosion protection.

Zinc alloy offers a premium look at a lower cost, providing an ideal balance between aesthetics, durability, and price compared with stainless steel or brass alternatives.

| Model | Material | Finish Options | Lever Length | Rose / Escutcheon | Door Thickness | Spindle | Suitable Lock Types |

|---|---|---|---|---|---|---|---|

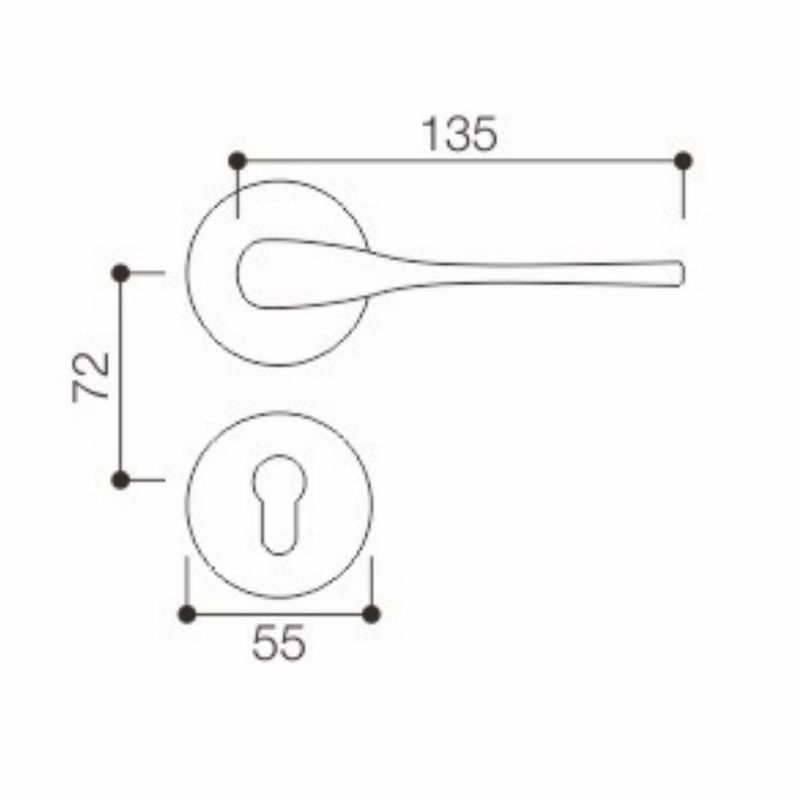

| Z1-1 Lever on Rose Set | Zinc Alloy | Matte Black (BL), Polished Gold (GD) | 135 mm | Ø55 mm round rose & euro profile escutcheon | 35–50 mm | 8 × 8 mm | Passage / Privacy / Euro Cylinder |

Polished Gold zinc-alloy door handle

Matte Black zinc-alloy door handle

| Parameter | Detail |

|---|---|

| Material | Zinc Alloy |

| Surface Treatment | Electroplated / Brushed / Polished |

| Handle Length | 120–135 mm |

| Rosette Diameter | 55–72 mm |

| Door Thickness Compatibility | 35–50 mm |

| Installation Method | Screw Fixing + Spindle Connection |

| Lock Type Compatibility | Euro Profile Cylinder, Privacy, or Passage |

Zinc alloy door handles are widely adopted across multiple environments due to their versatility, design flexibility, affordability, and durability. Foachi’s zinc alloy handles are engineered for smooth operation, stylish appearance, and long-term reliability, making them suitable for a wide range of projects and door systems.

Zinc alloy handles are ideal for modern home installations thanks to their elegant aesthetics and comfortable grip.

Typical uses include:

Bedroom doors

Bathroom and restroom privacy doors

Children’s room doors

Kitchen and pantry doors

Home office doors

Wardrobes and walk-in closet doors(smaller models)

Apartments and rental units

Why suitable: Zinc alloy provides excellent value with attractive finishes that match modern home décor.

The balance of durability and cost makes zinc alloy handles popular in commercial spaces with moderate foot traffic.

Common application areas:

Office doors

Conference rooms

Educational institutions(schools, training centers)

Retail stores and boutique shops

Clinics and medical offices(non-intensive areas)

Banks & financial service buildings

Shopping mall interior doors

Why suitable: Offers professional appearance + sturdy structure at a favorable price for bulk procurement.

Many hospitality projects use zinc alloy handles because they offer luxurious finishes at reasonable costs.

Suitable for:

Hotel guest room doors(interior)

Hotel bathrooms & connecting rooms

Restaurants and cafés

Bars and lounges

Resorts and leisure facilities

Why suitable: Electroplated finishes give a high-end, polished look without the high cost of brass.

Zinc alloy handles are an excellent fit for large-scale development projects due to their cost efficiency and consistency.

Applications include:

Residential buildings

Student housing & dormitories

Affordable housing projects

Airbnb, serviced apartments

Townhome and villa developments

Why suitable: Offers stable quality, variety of finishes, and easy installation for large projects.

Although zinc alloy is not intended for heavy-duty industrial environments, it performs well in controlled settings.

Suitable areas:

Factory offices

Staff break rooms

Storage rooms

Internal workshop doors(dry areas only)

Why suitable: Durable enough for indoors while cost-effective for multi-room facilities.

Zinc alloy handles come in numerous modern shapes and finishes, making them ideal for décor-driven projects.

Used in:

Interior design renovation

Boutique custom homes

Furniture integration(wardrobes、cabinet doors)

Minimalist/Scandinavian/Japandi interior themes

Modern luxury projects(polished gold / brushed nickel)

Why suitable: Designers love zinc alloy for its moldability—complex shapes and smooth contours are possible.

Zinc alloy handles can serve in medium-traffic public environments as long as humidity and corrosion are controlled.

Examples:

Libraries

Government offices

Museums & galleries

Community centers

Cultural institutions

Why suitable: Smooth operation and consistent looks fit public aesthetic standards.

Small-scale zinc alloy handles are widely used in:

Cabinets

Wardrobes

Drawers

Sideboards

TV cabinets

Bathroom vanities(sealed finish)

Why suitable: Provides high-end look for furniture at affordable cost.

To help customers choose the right handle material:

Indoor applications

Aesthetic-driven projects

Mid-traffic areas

Cost-sensitive construction

Modern or contemporary décor

Direct sunlight exposure

Coastal or high-humidity outdoor environments

Heavy industrial environments

If customers need high corrosion resistance, suggest stainless steel; if they want luxury feel and weight, suggest solid brass。

Align the spindle with the lock mechanism.

Insert handle through both sides of the door.

Tighten screws on the internal plate.

Attach the escutcheon or cover plate.

Check alignment and ensure smooth rotation.

Use the correct screw length for door thickness.

Avoid over-tightening to prevent deformation of the rosette.

Apply a small amount of thread-lock adhesive if handles loosen over time.

Cleaning: Wipe with a soft cloth and mild soap solution.

Avoid: Acidic or alcohol-based cleaners which can dull the finish.

Lubrication: Lightly oil the spindle and latch once per year.

Environment: Keep away from prolonged moisture exposure to prevent oxidation.

| Material | Durability | Corrosion Resistance | Cost | Typical Use |

|---|---|---|---|---|

| Zinc Alloy | High | Medium | $$ | Interior / Commercial |

| Aluminum | Medium | Medium | $ | Light Interior |

| Stainless Steel | Very High | Very High | $$$ | Exterior / Heavy Duty |

| Brass | High | Very High | $$$ | Luxury Applications |

✅ Conclusion: Zinc alloy provides the best value-to-performance ratio, especially for indoor and mid-range commercial projects.

Yes, zinc alloy handles are strong, corrosion-resistant, and provide a premium metallic finish at an affordable cost. They’re a popular choice for both residential and commercial applications.

Absolutely. Zinc alloy is non-toxic and safe for daily use. It’s commonly used in household hardware, faucets, and decorative fixtures.

Stainless steel offers superior strength and weather resistance, but zinc alloy wins in design flexibility and cost efficiency, making it ideal for indoor use.

Zinc alloy is economically efficient, not “cheap.” It’s chosen for its balance of affordability, weight, and finish options.

Yes—but it should be dried quickly after exposure to prevent oxidation over time.

Yes. It’s widely used in handles, knobs, and hinges for furniture and cabinetry thanks to its smooth finish and strength.

Brass has higher corrosion resistance and a heavier feel, while zinc alloy offers lighter weight and modern finish options at a lower cost.

Yes, it combines style, strength, and affordability, making it a top choice for modern hardware solutions.

With proper care and a high-quality plating process, zinc alloy handles can last 10–15 years or more.