close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-10-17 Origin: Site

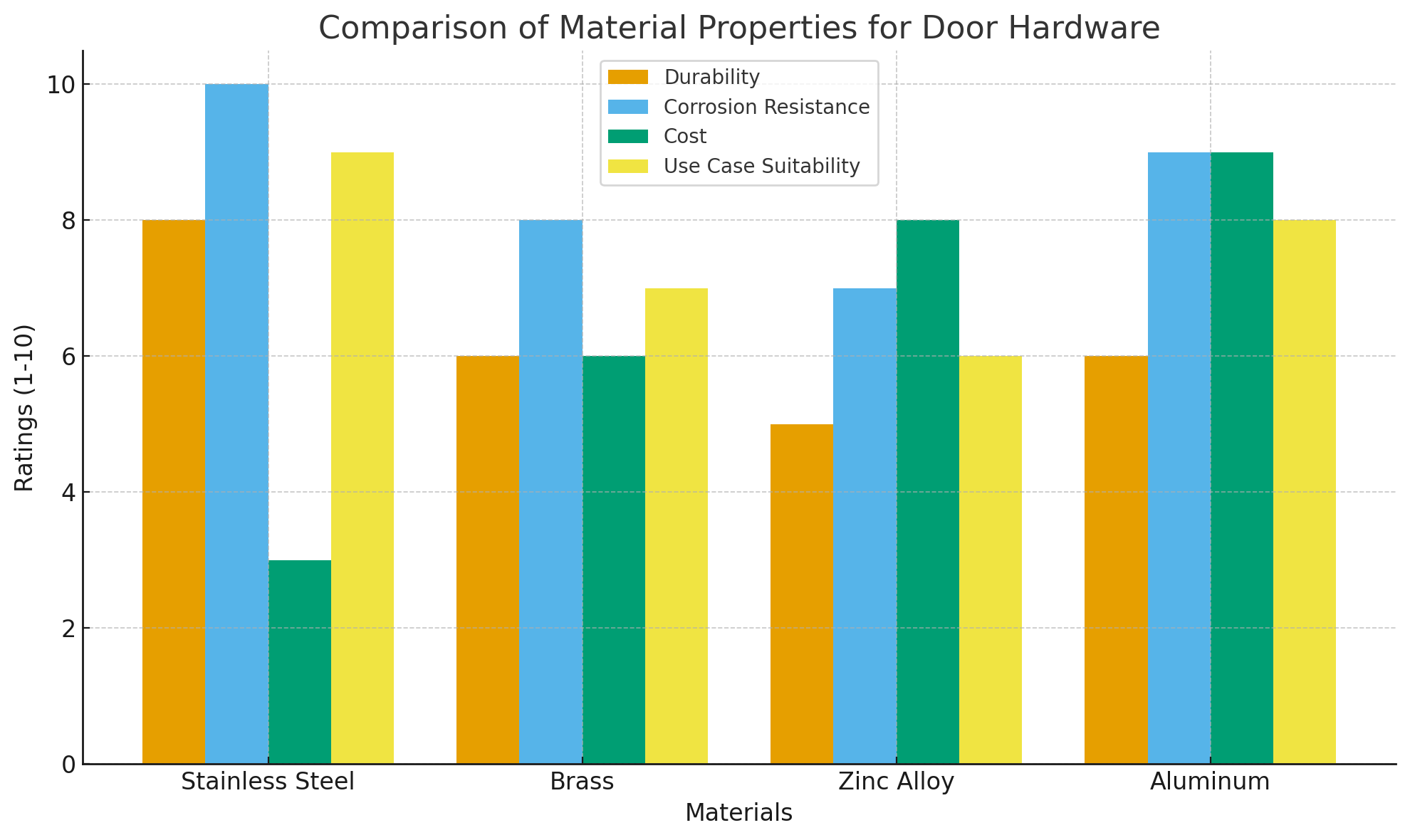

Choosing the right material for door hardware is essential for both style and performance. Whether you're upgrading your home or enhancing a commercial space, the material you select for your door handles significantly impacts durability, aesthetics, and functionality.

In this article, we will compare the four most popular materials used in door hardware—stainless steel, brass, zinc alloy, and aluminum. By exploring their advantages and disadvantages, you'll be equipped to make an informed decision for your next project.

Stainless steel is a widely chosen material for door hardware due to its exceptional strength, resistance to rust and corrosion, and sleek, modern appearance. Made primarily of iron, chromium, and a small percentage of carbon, stainless steel forms a protective layer of chromium oxide on its surface, which helps it resist damage from environmental factors. Stainless steel’s ability to maintain its integrity even under harsh conditions makes it ideal for both interior and exterior use.

In terms of door handles, stainless steel is favored for its durability, particularly in high-traffic areas. It can withstand heavy use, making it an excellent choice for commercial properties. Its versatility also allows it to blend well with contemporary, industrial, and modern aesthetics.

Brass is an alloy of copper and zinc, known for its warm, golden hue and classic, vintage appeal. Brass has been used in door hardware for centuries, valued not only for its aesthetic qualities but also for its durability. It is highly resistant to corrosion and tarnishing, which helps maintain its polished look over time. Its naturally antimicrobial properties make it particularly beneficial for areas where hygiene is important, like kitchens or healthcare environments.

Brass is often used for decorative and high-end hardware, including door handles, due to its ability to maintain both beauty and functionality. It also has a relatively low maintenance requirement, though it may need occasional polishing to maintain its shine.

Zinc alloy is a blend of zinc and other metals like aluminum, copper, and magnesium, offering a great balance of strength, cost-effectiveness, and design flexibility. It is a popular choice for affordable yet durable door hardware. Zinc alloy is often used for intricate designs, as it can be easily molded into complex shapes and finished in various styles, such as chrome or nickel plating.

While zinc alloy is durable, it is not as strong as stainless steel or brass. However, it provides a solid option for budget-conscious projects where cost-effectiveness is crucial without sacrificing too much on durability.

Aluminum is a lightweight and corrosion-resistant metal that is used in a wide range of door hardware applications. Its resistance to oxidation and ability to withstand the elements makes it an excellent choice for outdoor and coastal environments. Aluminum handles are often preferred in modern design due to their minimalistic and sleek look. Moreover, aluminum is highly versatile, available in various finishes, and can be anodized to provide additional protection against corrosion.

Although aluminum is not as durable as stainless steel, its light weight and easy installation make it ideal for residential and commercial properties where functionality and ease of use are prioritized over extreme durability.

When it comes to durability, stainless steel leads the pack. Its ability to resist wear, tear, and environmental damage makes it ideal for both high-traffic and outdoor environments. Brass, while durable, may require more care due to its tendency to tarnish over time. Zinc alloy is suitable for light-duty applications but lacks the strength to withstand heavy-duty use, and aluminum, while strong for its weight, is not as resilient under pressure as stainless steel or brass.

All four materials offer varying levels of corrosion resistance, which is crucial when selecting door hardware for environments exposed to moisture. Stainless steel excels in corrosion resistance, making it perfect for bathrooms and exterior doors. Brass also resists corrosion well but may tarnish over time, especially in humid conditions. Zinc alloy is moderately resistant to rust but is less durable than stainless steel in extreme weather conditions. Aluminum, known for its corrosion resistance, is particularly suited for coastal environments or areas with high humidity.

Aesthetic appeal varies greatly between materials. Stainless steel provides a sleek, modern finish that fits well in contemporary settings, often used in industrial or minimalist designs. Brass, with its rich golden tone, is a classic choice that exudes elegance and works well in vintage or luxurious interior spaces. Zinc alloy can be finished in a variety of ways, offering a versatile design option that mimics more expensive materials. Aluminum, while modern, has a more utilitarian look, typically used in minimalist or industrial design schemes.

Aluminum is by far the lightest material, making it easy to handle and install. This makes it an excellent option for DIY projects or areas where frequent adjustments are necessary. Stainless steel, while heavier, provides greater strength, making it ideal for securing heavy doors. Brass is heavier than aluminum but lighter than stainless steel. Zinc alloy is lightweight but not as easy to install as aluminum.

Material | Durability | Corrosion Resistance | Cost | Best For |

Stainless Steel | High | Excellent | High | High-traffic areas, outdoor use, commercial properties |

Brass | Medium | High | Medium | Luxury, decorative, vintage designs |

Zinc Alloy | Moderate | Moderate | Low | Budget-friendly, interior applications |

Aluminum | Moderate | High | Low | Modern, lightweight, outdoor settings |

Zinc alloy is the most affordable option among these materials, making it a great choice for projects on a budget. Aluminum is also relatively cost-effective, though slightly more expensive than zinc alloy. Stainless steel and brass, due to their durability and aesthetic appeal, are more expensive but provide long-term value due to their strength and longevity.

Stainless steel offers the highest value in terms of long-term durability, requiring minimal maintenance while maintaining its strength and appearance over the years. Brass needs periodic polishing to maintain its shiny appearance, while zinc alloy may wear more quickly if exposed to harsh environments. Aluminum, while low-maintenance, can become scratched or dented over time, especially in high-traffic areas.

For budget-conscious buyers, zinc alloy and aluminum provide excellent value without compromising too much on functionality or design flexibility. These materials are ideal for projects where cost is a major factor, and the demand for extreme durability is lower.

Material | Initial Cost | Maintenance Cost | Long-Term Value |

Stainless Steel | High | Low | High |

Brass | Medium | Medium | High |

Zinc Alloy | Low | Low | Moderate |

Aluminum | Low | Low | Moderate |

If you need door hardware for high-security areas, stainless steel is your best bet. Its strength and corrosion resistance make it ideal for both residential and commercial applications. For decorative yet durable solutions, brass is a great option. Zinc alloy and aluminum should be considered for lighter-duty applications where ease of installation and cost are more important than maximum durability.

Choosing the right material often comes down to design preferences. If you're looking for a modern, industrial feel, stainless steel or aluminum will fit well. For a vintage or luxury look, brass is the ideal choice. Zinc alloy offers a good balance between cost and design flexibility, while aluminum’s minimalist design is perfect for contemporary settings.

If your door hardware will be exposed to the elements, such as in coastal or humid areas, stainless steel and aluminum are the best materials due to their resistance to corrosion. Brass and zinc alloy may require additional protection in these environments.

Stainless steel door hardware is perfect for areas with high foot traffic and harsh environments. Its ability to withstand wear and corrosion makes it ideal for both residential and commercial spaces.

Brass is best suited for luxury homes or vintage-style interiors. Its elegance and antimicrobial properties make it a popular choice for decorative applications in both residential and commercial properties.

For those on a budget, zinc alloy provides a cost-effective option that still offers durability and design flexibility. It’s ideal for interior doors, furniture, and other light-duty applications.

Aluminum is perfect for modern designs, particularly in coastal areas where corrosion resistance is crucial. Its lightweight nature makes it a great choice for doors that are used frequently.

Material | Best Use Case(s) | Environment Compatibility |

Stainless Steel | High-traffic areas, exterior doors, commercial spaces | Outdoor, humid, coastal areas |

Brass | Luxury homes, decorative door handles, vintage designs | Indoor, dry climates |

Zinc Alloy | Budget-conscious applications, interior doors | Indoor, moderate humidity |

Aluminum | Modern designs, lightweight applications, coastal settings | Outdoor, humid, coastal areas |

Pros: Long-lasting, low-maintenance, corrosion-resistant, modern aesthetic.

Cons: Expensive, heavy.

Pros: Aesthetic appeal, antimicrobial properties, durable.

Cons: Requires regular polishing, can tarnish over time.

Pros: Cost-effective, versatile in design, decent durability.

Cons: Less durable than stainless steel or brass.

Pros: Lightweight, corrosion-resistant, cost-effective.

Cons: Less durable under heavy use, scratches easily.

Material | Advantages | Disadvantages |

Stainless Steel | Long lifespan, corrosion-resistant, easy maintenance | Higher cost |

Brass | Elegant, antimicrobial, durable | Requires regular polishing |

Zinc Alloy | Budget-friendly, versatile | Limited durability in high-stress areas |

Aluminum | Lightweight, corrosion-resistant, cost-effective | Lower strength compared to steel |

Choosing the right material for your door hardware is crucial for balancing aesthetics, durability, and cost. Stainless steel and brass are great for premium fixtures, offering long-lasting durability. Zinc alloy and aluminum are more budget-friendly options while still providing excellent functionality. When selecting your material, consider environmental factors, maintenance needs, and design preferences.

For high-quality door hardware, Foachi provides a range of durable and aesthetically appealing options in stainless steel, brass, zinc alloy, and aluminum to meet your needs.

A: Stainless steel offers durability and resistance to corrosion, while brass provides a classic aesthetic. Zinc alloy is more budget-friendly, and aluminum is lightweight and corrosion-resistant.

A: Brass offers a classic, elegant look and natural antimicrobial properties. It's ideal for high-end door handles and fixtures but requires regular maintenance.

A: Aluminum is lightweight, corrosion-resistant, and suitable for modern designs. It works well in both interior and exterior settings but may not be as strong as stainless steel.

A: Stainless steel is highly durable and resistant to corrosion, making it ideal for high-traffic areas. It's more expensive than zinc alloy or aluminum but offers long-term reliability.